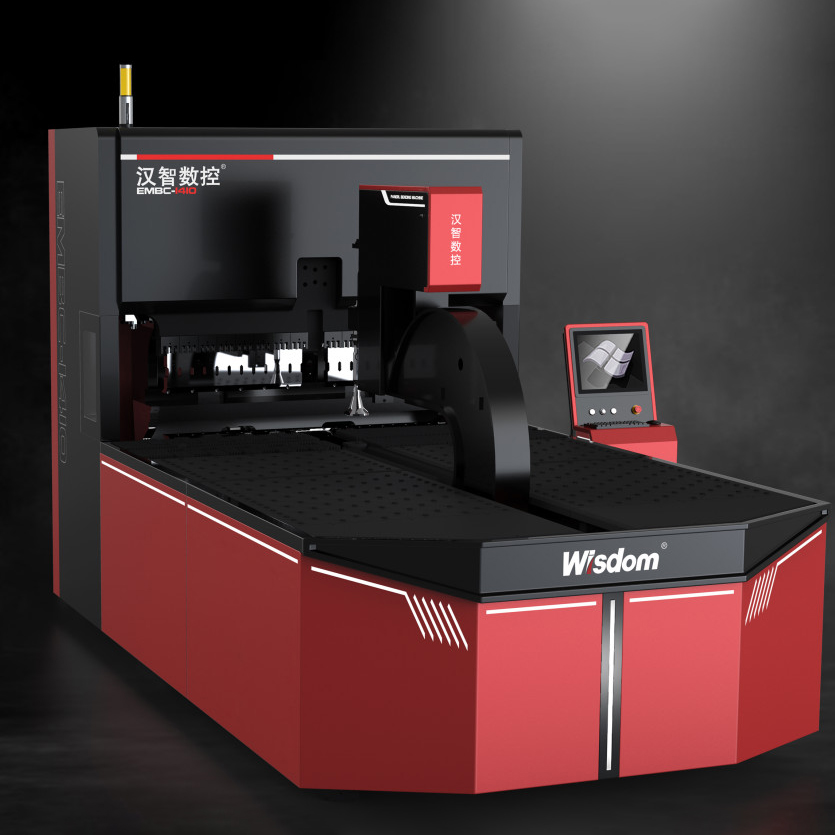

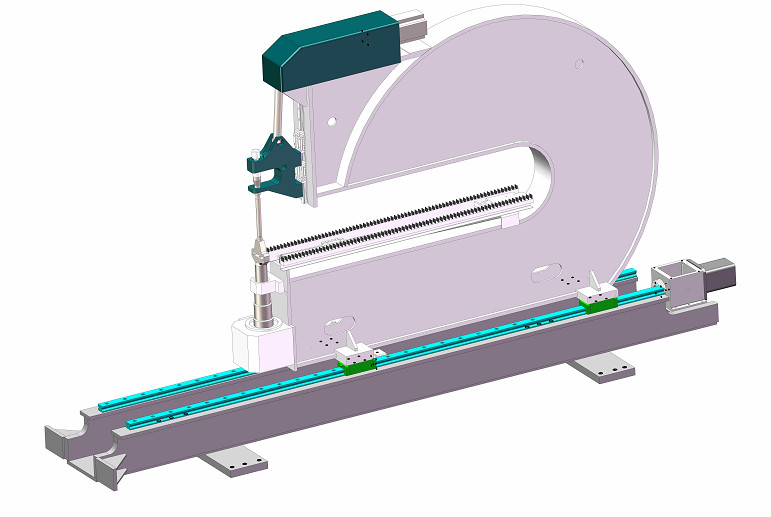

Semi-otomatiki Panel Bender EMBC 1402

products specification

| Aihwa. | Zita | Parameter | Unit |

| 1 | Max.kureba | 1400 | mm |

| 2 | Max.width | 1400 | mm |

| 3 | Min.Kukombama kureba | 200 | mm |

| 4 | Min.kukotama upamhi | 260 | mm |

| 5 | Max.bending ukobvu (MS,UTS410N/mm²) | 1 | mm |

| 6 | Min.bending ukobvu (MS,UTS410N/mm²) | 0.5 | mm |

| 7 | Max.kukotama urefu | 170 | mm |

| 8 | Kureba kugadzirisa maitiro ekumusoro press Manual | ||

| 9 | Avhareji yekushandisa simba | 2.2 | KW |

| 10 | Kurema | 15 | T |

Hunhu uye chimiro chikuru

Panyaya yekugadzira muchina nekugadzira, Hebei Hanzhi CNC Machinery Co.,Ltd.inonyanya kutarisa pane zvinotevera:

1. Pfungwa yekushambadzira inoteedzera kuita uye inochengetedza mushandisi peni yega yega.

2. Yakavimbika uye yakanyatso dhizaini pfungwa.

3. Yepamusoro-mhando mbishi, zvikamu zvakatengwa uye yakanakisa nzira dzekugadzirisa.

4. Kunyanya kusimbiswa kwekureruka kwekushandisa uye kuchengetedza nekuchengeteka.

5. Mutengo wekuchengetedza wakaderera uye mutengo wekugadzirisa mune imwe indasitiri.

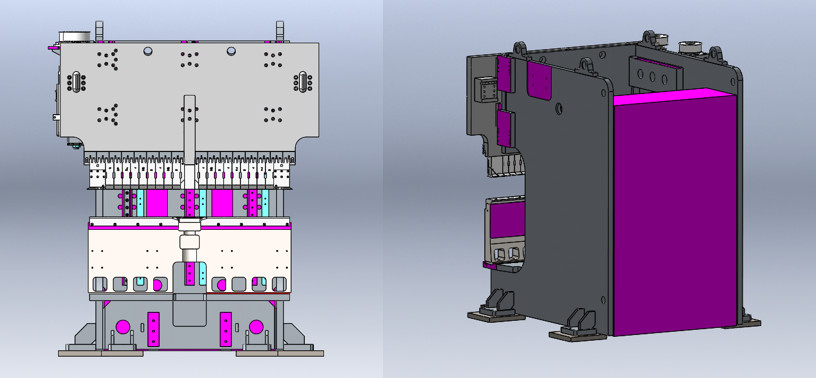

furemu

A. Kuvaka 3D inogumira modhi: Zvichienderana neyakagadziridzwa uye yakagadzirwa 3D yakasimba modhi, ine simba inogumira element modhi inogadzirirwa kuverenga.Iyo modhi inotarisa iyo huru zvikamu pane iyo simba rekufambisa kubatana.Masimba anotamirwa kune kutakura kuburikidza nekubatanidza uye ipapo kuongororwa kwesimba kwekutakura kunoitwa.

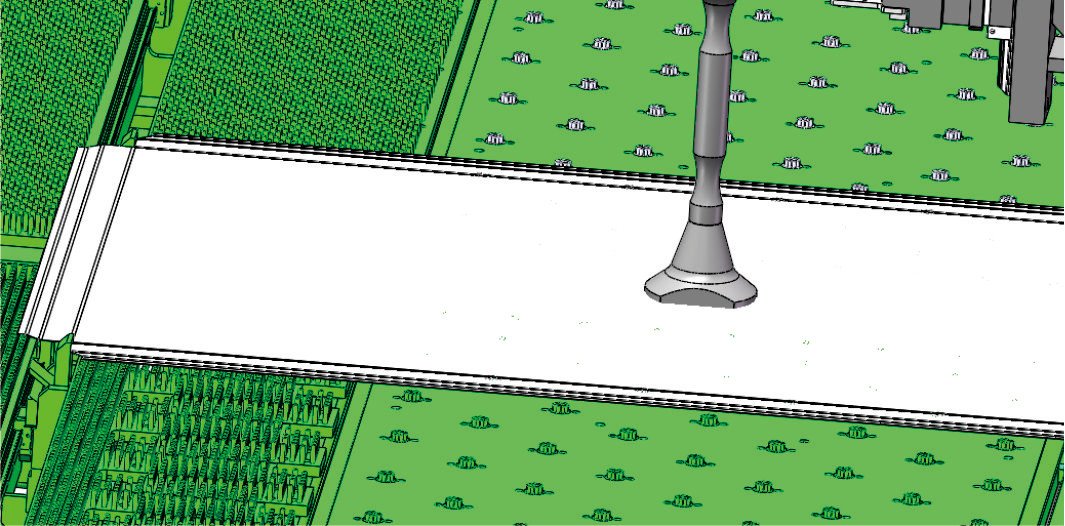

Fig. 1 Panel bender Finite element dynamic modeling yemuchina wakakwana

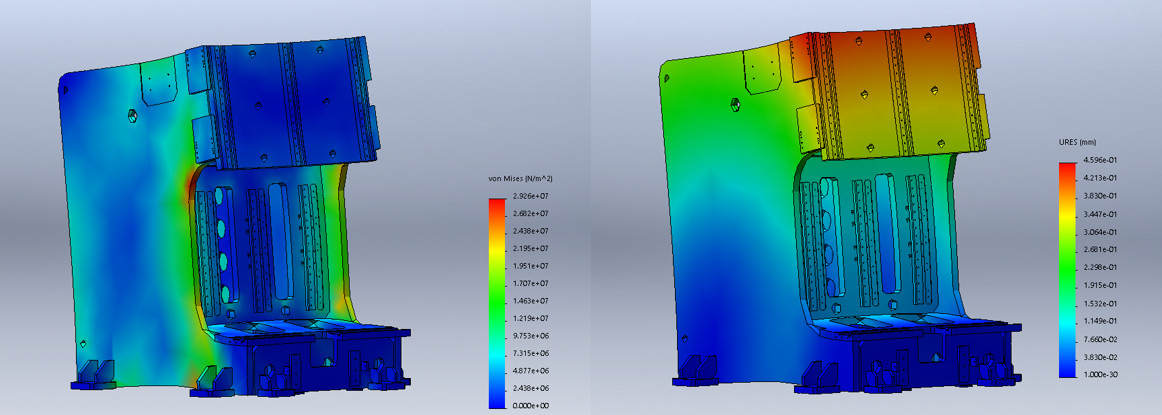

B. Kuongorora kweStatic Analysis Results: Pamusana pekunonoka kwekugadzira machining, kuongorora kwesimba kunogona kuderedzwa kusvika kune static dambudziko.Zvichienderana neplate yekumanikidza mutoro uye kukotama mutoro munzira yakatwasuka yemusoro wekucheka, kushushikana uye deformation mhedzisiro inoratidzwa pazasi.Kunyanya kushushikana kunoonekwa muhuro yemuviri nekunyanya kushushikana kwe21.2mpa uye iyo yakanyanya deformation inoonekwa kumucheto wepamusoro wemuviri uine deformation yakakura ye0.30mm.

Zvinoenderana neinogumira chinhu chekuongorora mhedzisiro yefuremu, Q345 simbi yakasarudzwa sechinhu;carbon dioxide shield welding yakagamuchirwa;Kupisa kurapa kwakaitwa kuti kubvise kushushikana kunokonzerwa newelding;nokudaro kuve nechokwadi chekururama, kugadzikana uye kusimba kwepamusoro kwemidziyo yekushanda kwenguva refu.

Fig. 2 stress displacement deformation analysis results of frame

Gondohwe repamusoro

Ichi chikamu chinonyanyo sanganisira inotsvedza, yakakwira torque lead screw, reducer, gwara renjanji, servo mota zvichingodaro.Iyo huru dhiraivha inodzorwa ne servo mota uye iyo yekudzora modhi ndeye servo synchronous control, iyo inogona kunyatso kuve nechokwadi chekumisikidza kurongeka, kukurumidza kumhanya uye yakakwirira controllability.Kuzora kweiyo lead screw uye gwara renjanji kunotora otomatiki lubrication, uye girizi iri 00 #, iyo inovimbisa hupenyu hwesevhisi uye nemazvo eiyo lead screw uye njanji yekutungamira kwenguva yakareba kushanda.

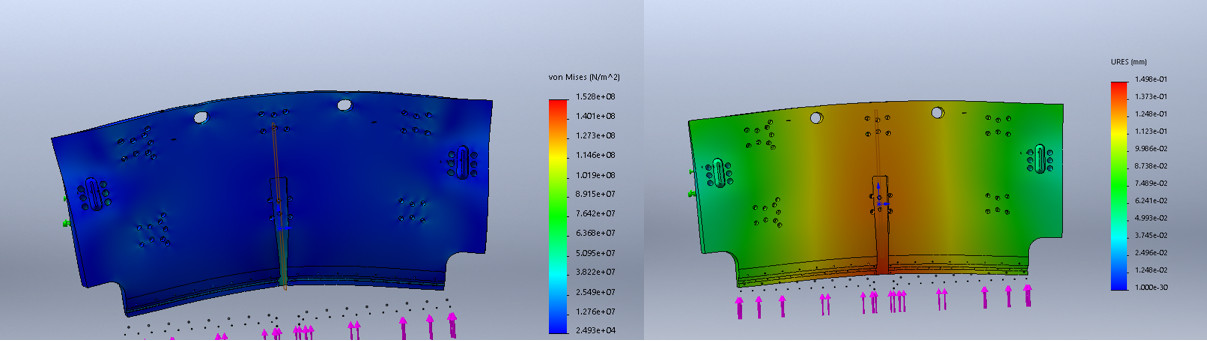

Static kuongororwa mhedzisiro yekumusoro inotsvedza: iyo stress displacement itsvo dhizaini yetafura yepamusoro inoratidza kuti yakanyanya kushushikana inoonekwa muchikamu chepamusoro, iyo yakanyanya kushushikana ndeye 152mpa, iyo yakanyanya deformation inoonekwa kumucheto wepamusoro wetafura, iyo yakanyanya deformation. iri 0.15mm

Fig. 3 stress displacement analysis migumisiro yegondohwe

Zvinoenderana neinogumira chikamu chekuongorora mhedzisiro yegondohwe, Q345 simbi yakasarudzwa sechinhu;CO2 shielded welding yakashandiswa;tempering kurapwa kwakaitwa kubvisa kushushikana kunokonzerwa ne welding;nokudaro kuve nechokwadi chekururama, kugadzikana uye kusimba kwepamusoro kwemidziyo yekushanda kwenguva refu.

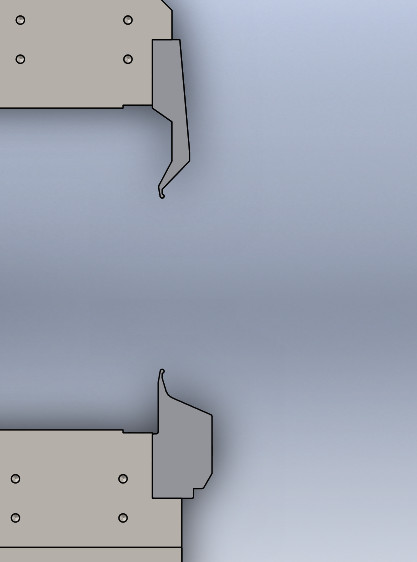

Bending unit

Iyo simba dhiraivha chikamu cheiyo bending unit inofambiswa ne servo mota pasina kubatanidzwa kweiyo hydraulic system, iyo ine mabhenefiti makuru maererano nekudzikisa kupfeka uye kubvaruka kwezvikamu uye kugona kutapurirana, zvinoenderana nekuchengetedza simba uye kuchengetedza nharaunda mutemo unotsigirwa. nenyika.

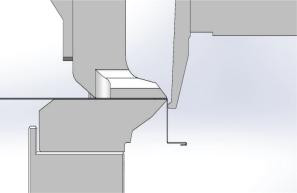

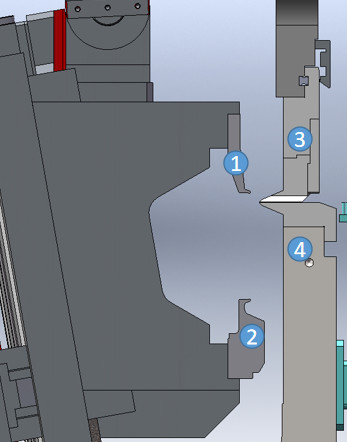

Zvinoenderana nekumisikidzwa kweruzivo rwebepa, sisitimu inongoverengera chinzvimbo chepamusoro chepamusoro banga 3 uye inodzora chinhambwe pakati peyepamusoro pepa banga 3 uye yepasi yekutsikisa banga 4 kugadzirisa pepa;zvinoenderana nehurongwa hwekumisikidza, kungave uku kukotama kuri kumusoro kana pasi, banga repasi rekutsikirira 2 kana banga repamusoro rekudzvanya 1 rinodzorwa kuti rifambe nekukurumidza kuenda kunzvimbo yekukotama;zvinoenderana nemakona ekuseta akasiyana, banga rinokotama rinodzorwa kuti riende kunzvimbo yakaverengerwa kuburikidza neiyo patented angle calculation formula kuti ipedze kukotama.

Zvinoenderana nemhando dzakasiyana dzekukotama, inogona kupatsanurwa kuita kona yekukotama, yakakura arc kukotama, kupepeta kubhenda, nezvimwewo, iyo kona yekukotama yakakamurwa kuita kubhenda kumusoro uye kudzika pasi.

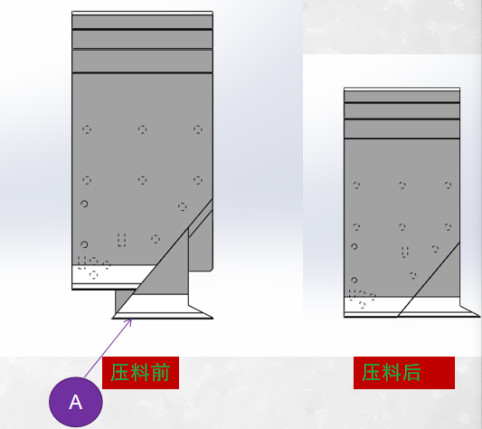

Upper press unit

Fig.6 Upper press unit

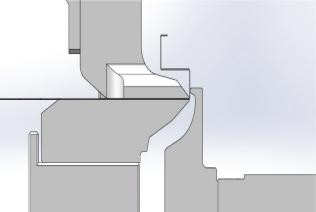

Iyo yekumusoro yekutsikirira unit: chikamu chese maitiro ekukotama, iyo EmbC yakazara servo multilateral bending centre ine yakakosha yekumusoro yekutsikisa unit iyo inogona kuisirwa uye kugadziridzwa nemaoko kune akasiyana maplate urefu.

Kuti tisangane nezvinodiwa zvekudzivirira kubhenda bhokisi, isu takagadzira yakakosha yekudzivirira kufa.Usati wadzvanya, chikamu chekudzivirira kufa chiri muhurumende isati yadzvanya mudhayagiramu uye kudya kunotanga.Mushure mekudya, iri mudunhu mushure mekudzvanya mudhayagiramu uye kukotama kunotanga.Mushure mekukotama, mutsetse wepamusoro unofamba.Panguva yekufamba kweyepamusoro inotsvedza, chikamu A chinozongoenda kune iyo nyika isati yadzvanya.Mushure mekunge musevedzeri wepamusoro waenda kunzvimbo yakatarwa, kufamba kunotevera kunotanga.

Fig.7 Kupeta bhokisi kudzivisa

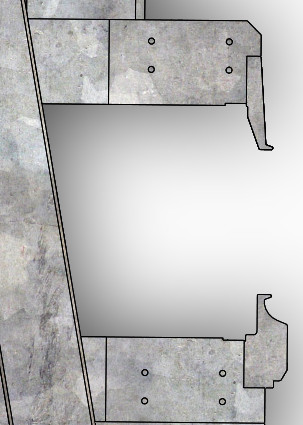

Tool

Maturusi ekubhenda akakamurwa kuva maturusi ekubhenda epamusoro uye maturusi ekubhenda epasi.Zvishandiso zvekukotama zvakakosha zvinogona kugadzirwa zvinoenderana nezvinodiwa zvakasiyana zvemutengi.

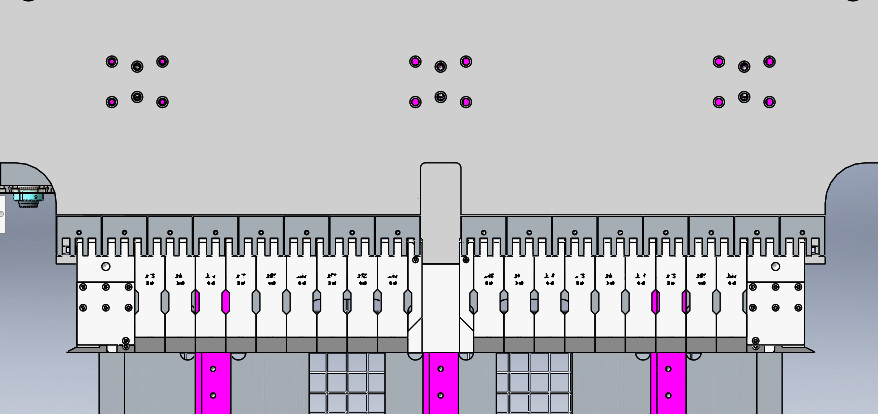

2.Plate feeding unit:

Kufamba, kusungirira uye kutenderera kwesimbi simbi kunodzorwa nerobhoti 1, iyo 2 uye inotenderera disc 3 zvichiteerana.Munguva yese yekugadzira machining, kudyisa kwepepa simbi kunodzorwa ne servo motors, kugonesa otomatiki uye nekukurumidza chinzvimbo, kuderedza nguva dzekufamba uye kuwedzera kugona.Kutenda kune hunyanzvi hwekugadzira uye kushandiswa kwesevha yakazara kutonga, iyo clamping uye kutenderera kwepepa simbi inokwanisa kuchengetedza iko kurongeka mukati mekushanda kwenzvimbo yakawanda yekubhenda.Kune akawanda akaomarara workpieces, kunyangwe ayo epolygonal, kuenderera kutenderera kutenderera kwe0.001 kunogona kuvimbiswa.

3.Plate positioning unit:

Iyo plate positioning unit ine yekuruboshwe pini yekumisikidza, yekurudyi yepini yekumisikidza, yekumberi yepini uye yekumashure yepini;mapini ekuisa kuruboshwe nekurudyi anoisa ndiro kuruboshwe nekurudyi.Pini yekumisikidza yekumberi uye yekumashure yepini inodzora kumberi nekumashure kweplate uye ive nechokwadi chekuti ndiro yakaenzana nepamusoro nepasi mapanga ekutsikirira, ayo anoshandiswa kuve nechokwadi chekumira kweplate.

Iyo plate positioning unit inokwanisa kumisa ndiro yacho otomatiki kupeta kwakawanda panguva imwe chete, iyo inopfupisa zvakanyanya nguva yekukotama, inodzora kukanganisa kwekugera kweplate pakutanga kubhenda uye inova nechokwadi chekupeta.

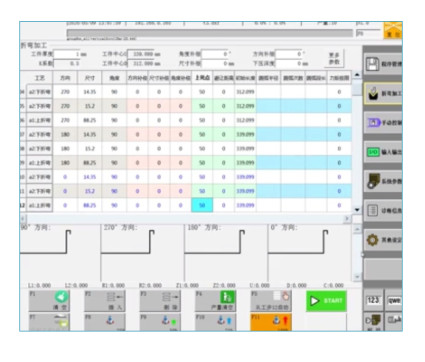

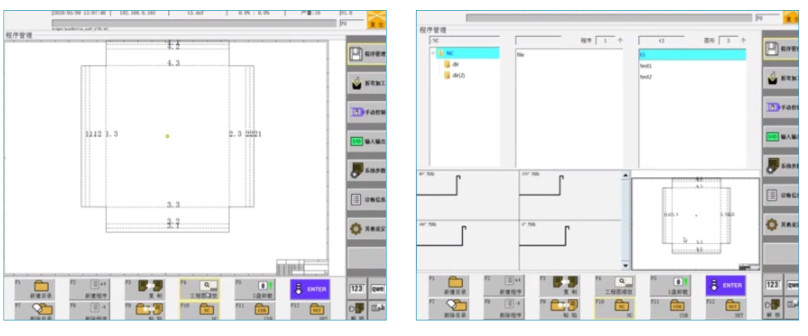

4.CNC system

A: Akabatana akagadziridzwa CNC masisitimu uye software inogona kuiswa uye kutungamirirwa nekukurumidza uye nyore

B: Zvinhu zvakakosha.

a) .EtherCAT bhazi yekudzora nzira ine yakakwirira kupindira kuramba

b) Inotsigira yakananga hurongwa, kukotama data kune yega yega nhanho inogona kuiswa mufomu

c) Tsigiro yekukotama yakakombama

d) Yakazara yemagetsi servo control

e) Tsigiro yekubhenda muripo

f) Tsigiro yezvikamu zviviri-mapurogiramu

2D programming basa, pinza 2D DXF yekudhirowa data, inoburitsa otomatiki maitiro ekukotama, saizi yekukotama, kona yekukotama, kona yekutenderera uye imwe data.Mushure mekusimbiswa, otomatiki bending processing inogona kuitwa

Rondedzero yechikamu chikuru

| Aihwa. | Zita | Brand |

| 1 | Frame | Uchenjeri |

| 2 | Tool | Uchenjeri |

| 3 | Bending unit | Uchenjeri |

| 4 | CNC System | Uchenjeri |

| 5 | Servo injini | Uchenjeri |

| 6 | Servo mutyairi | Uchenjeri |

| 7 | Rail | Uchenjeri |

| 8 | Ballscrew | Uchenjeri |

| 9 | Reducer | Taiwan |

| 10 | Breaker | Schneider |

| 11 | Bhatani | Schneider |

| 12 | Chikamu chemagetsi | Schneider |

| 13 | Cable | Yicu |

| 14 | Proximity switch | Omroni |

| 15 | Bearing | SKF/NSK/NAICH |

4) Dhizaini, kugadzira, kuongorora uye kuisirwa kwechishandiso chemuchina kunosangana nezvinotevera zviyero.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Spare part uye tool list

| Aihwa. | Zita | Qt. | Remark |

| 1 | Tool box | 1 | |

| 2 | Isa padhi | 8 | |

| 3 | Inener hexagon spanner | 1 set | |

| 4 | Manual refueling pfuti | 1 | |

| 5 | CNC system manual | 1 | |

| 6 | vhura sipani | 1 |